Eventuri Carbon Turbo Inlet (Gen 2 RHD) - Audi RS3 (8V) & TTRS (8S)

-

Fast Dispatch on In Stock Items

-

100% Original & Quality Guarantee

-

Free Customer Support

*** PLEASE SELECT CORRECT FLANGE AS FITMENT DEPENDS ON TURBO ***

- - Stock Turbo

- - TTE 700 / 625

- - SRM GTX3582

PLEASE NOTE FITMENT FOR FACE LIFT 2017 ONWARD (294KW) MODELS ONLY.

Performance Gain (RS3 with Hybrid Turbo): 14-20hp, 30-35ft-lb

Flow Rate increase at 24″ H2O : 42% increase over stock (Using Stock Flange)

Fitment for RS3 8V Gen 2 and TTRS 8S Left and Right hand drive. Finished in raw carbon – no clearcoat.

Optional Turbo flanges available for popular hybrid turbos.

Presenting a World First – an all carbon RS3/TTRS turbo inlet elbow. We have invested months of intense R&D in developing an inlet which leaves no room for compromise. VOLUME – FLOW QUALITY – TEMPERATURE are the 3 main design criteria which we sought to meet.

1) VOLUME : Inlet Diameters – Eventuri 103mm : Stock 72mm. Outlet Diameters – Eventuri 74mm : Stock 56.4mm. Clearly with significantly larger internal diameter sizes, the Eventuri elbow encapsulates a much larger internal volume which de-restricts the flow path to the turbo.

2) FLOW QUALITY : Having just a large internal volume is no good unless the flow path also allows for smooth airflow to the turbo. By using high temperature Prepreg Carbon Fiber we have managed to achieve a smooth internal surface. In contrast, the stock and other aftermarket elbows are all made from cast aluminium which end up with a rough internal surface. This coupled with the smooth curvature of the elbow results in a flow path which minimises turbulence.

3) TEMPERATURE : The final criteria was to minimise the conduction of heat into the airflow. The stock inlet is directly connected to the turbo and so immediately conducts heat as the turbo spools. Our system uses a machined flange which connects to the turbo and then a silicon coupler with an integrated thermal spacer to keep the carbon elbow from having direct contact with the turbo. This barrier coupled with the low through-thickness thermal conductivity of carbon fiber results in less heat being transferred to the airflow.

The Eventuri RS3 8V / TTRS 8S Turbo Inlet is manufactured from high temperature prepreg carbon fiber and come with a number of other components engineered to perform a specific purpose and fabricated to the highest of standards.

Fitment is available for RHD and LHD Vehicles. The inlet is designed to fit our Stage 2 and Stage 3 RS3 8V / TTRS 8S intake systems

Here are the details for each component and the design ethos behind them:

Each inlet system consists of:

- High Temperature Carbon Inlet Elbow - RHD and LHD Specific

- CNC Machined Turbo Flanges - optional choices

- Silicon Couplers With Oil Resistant Lining

- Marine Grade Stainless Steel Hose Clamps

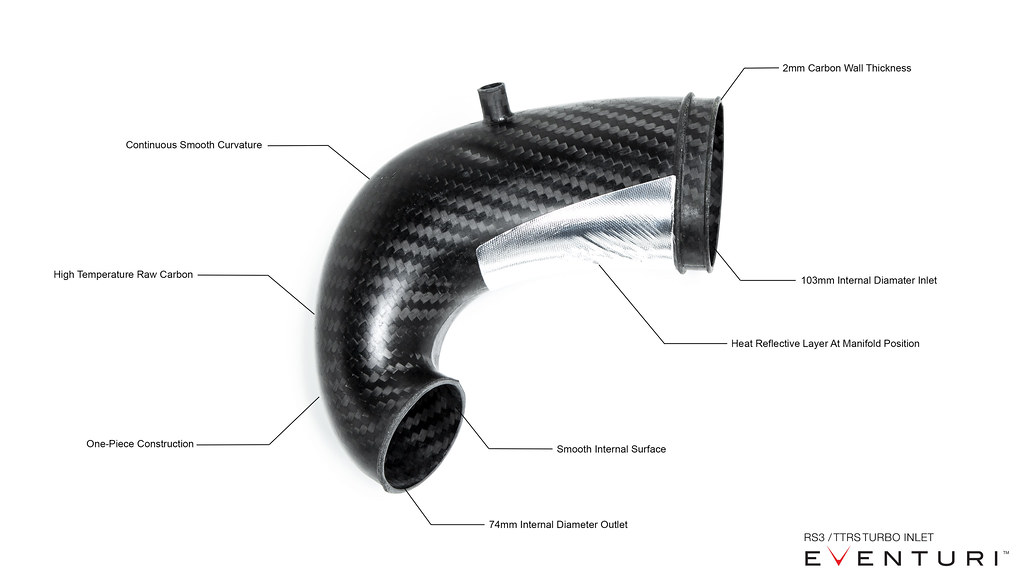

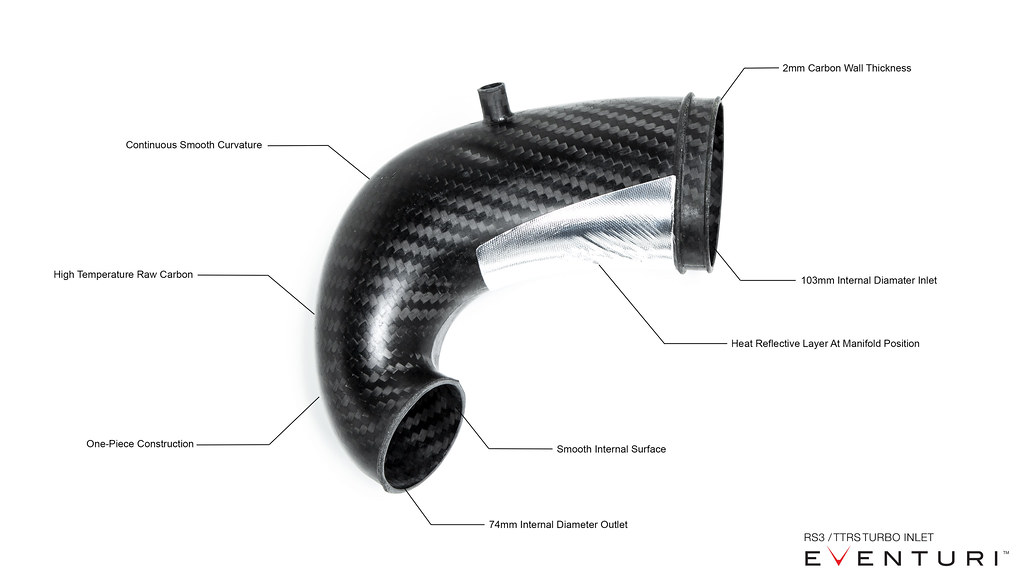

Carbon Fiber Inlet Elbow

Our Turbo Inlet provides a smooth flow path from the 103mm diameter inlet to the 74mm outlet to the turbo flange. We designed the shape with a continuous curvature and maximised the internal volume without affecting the airflow negatively. The inlet is finished in raw carbon so has no clear coat - which would not be able to withstand the heat generated from the turbo and exhaust manifold. The carbon construction allows us to keep the inside flow surface smooth which helps with reducing the surface friction and in turn allows airflow to move easier. We ensure strength and rigidity by maintaining a 2mm wall thickness throughout the part. Finally for added protection there is a heat reflective layer applied where the tube crosses the exhaust manifold. This reduces the radiant heat absorbed by the tube. The advantage of using carbon fiber over the traditionally used cast aluminium is mainly down to the thermal conductivity and the ability to keep the inside smooth. The table below summarises the advantages.

Minimising Heat Soak

When the RS3/TTRS accelerates, the turbo generates intense heat as it spools. Since the face of the turbo is directly connected to our CNC machined flange, we designed a silicon coupler to also act as a thermal barrier between the carbon tube and the metal flange. Internally the silicon has a spacer which separates the carbon and metal surfaces. This reduces the conductive heat transfer and therefore allows power to remain more constant since the inlet does not heat soak as quickly as the stock inlet does.

CNC Machined Turbo Flanges

We provide a choice of turbo flanges which are all CNC machined from aircraft grade aluminium and anodised. We will also be adding more flanges for new hybrid turbos coming to the market.

Currently Available Flanges:

- Stock Turbo

- TTE 700 / 625

- SRM GTX3582

Please inquire for other fitments.

*** PLEASE SELECT CORRECT FLANGE AS FITMENT DEPENDS ON TURBO ***

- - Stock Turbo

- - TTE 700 / 625

- - SRM GTX3582

PLEASE NOTE FITMENT FOR FACE LIFT 2017 ONWARD (294KW) MODELS ONLY.

Performance Gain (RS3 with Hybrid Turbo): 14-20hp, 30-35ft-lb

Flow Rate increase at 24″ H2O : 42% increase over stock (Using Stock Flange)

Fitment for RS3 8V Gen 2 and TTRS 8S Left and Right hand drive. Finished in raw carbon – no clearcoat.

Optional Turbo flanges available for popular hybrid turbos.

Presenting a World First – an all carbon RS3/TTRS turbo inlet elbow. We have invested months of intense R&D in developing an inlet which leaves no room for compromise. VOLUME – FLOW QUALITY – TEMPERATURE are the 3 main design criteria which we sought to meet.

1) VOLUME : Inlet Diameters – Eventuri 103mm : Stock 72mm. Outlet Diameters – Eventuri 74mm : Stock 56.4mm. Clearly with significantly larger internal diameter sizes, the Eventuri elbow encapsulates a much larger internal volume which de-restricts the flow path to the turbo.

2) FLOW QUALITY : Having just a large internal volume is no good unless the flow path also allows for smooth airflow to the turbo. By using high temperature Prepreg Carbon Fiber we have managed to achieve a smooth internal surface. In contrast, the stock and other aftermarket elbows are all made from cast aluminium which end up with a rough internal surface. This coupled with the smooth curvature of the elbow results in a flow path which minimises turbulence.

3) TEMPERATURE : The final criteria was to minimise the conduction of heat into the airflow. The stock inlet is directly connected to the turbo and so immediately conducts heat as the turbo spools. Our system uses a machined flange which connects to the turbo and then a silicon coupler with an integrated thermal spacer to keep the carbon elbow from having direct contact with the turbo. This barrier coupled with the low through-thickness thermal conductivity of carbon fiber results in less heat being transferred to the airflow.

The Eventuri RS3 8V / TTRS 8S Turbo Inlet is manufactured from high temperature prepreg carbon fiber and come with a number of other components engineered to perform a specific purpose and fabricated to the highest of standards.

Fitment is available for RHD and LHD Vehicles. The inlet is designed to fit our Stage 2 and Stage 3 RS3 8V / TTRS 8S intake systems

Here are the details for each component and the design ethos behind them:

Each inlet system consists of:

- High Temperature Carbon Inlet Elbow - RHD and LHD Specific

- CNC Machined Turbo Flanges - optional choices

- Silicon Couplers With Oil Resistant Lining

- Marine Grade Stainless Steel Hose Clamps

Carbon Fiber Inlet Elbow

Our Turbo Inlet provides a smooth flow path from the 103mm diameter inlet to the 74mm outlet to the turbo flange. We designed the shape with a continuous curvature and maximised the internal volume without affecting the airflow negatively. The inlet is finished in raw carbon so has no clear coat - which would not be able to withstand the heat generated from the turbo and exhaust manifold. The carbon construction allows us to keep the inside flow surface smooth which helps with reducing the surface friction and in turn allows airflow to move easier. We ensure strength and rigidity by maintaining a 2mm wall thickness throughout the part. Finally for added protection there is a heat reflective layer applied where the tube crosses the exhaust manifold. This reduces the radiant heat absorbed by the tube. The advantage of using carbon fiber over the traditionally used cast aluminium is mainly down to the thermal conductivity and the ability to keep the inside smooth. The table below summarises the advantages.

Minimising Heat Soak

When the RS3/TTRS accelerates, the turbo generates intense heat as it spools. Since the face of the turbo is directly connected to our CNC machined flange, we designed a silicon coupler to also act as a thermal barrier between the carbon tube and the metal flange. Internally the silicon has a spacer which separates the carbon and metal surfaces. This reduces the conductive heat transfer and therefore allows power to remain more constant since the inlet does not heat soak as quickly as the stock inlet does.

CNC Machined Turbo Flanges

We provide a choice of turbo flanges which are all CNC machined from aircraft grade aluminium and anodised. We will also be adding more flanges for new hybrid turbos coming to the market.

Currently Available Flanges:

- Stock Turbo

- TTE 700 / 625

- SRM GTX3582

Please inquire for other fitments.

Return Policy

Shipping

We understand how difficult it can be to find good quality parts at affordable prices. Our goal is to offer reliable parts at a price everyone can afford. We send out hundreds of parts every week through various courier companies. Unfortunately these companies do not offer freight insurance on our larger product range.

Please note that with this product range we do offer shipping, however, these items are sent at buyer risk. Therefore, if you have ordered one of these panels and it sustains any damage during transit the onus falls onto the buyer. Obviously we are supplying a brand-new product and we intend for the product to arrive in the same condition it leaves our distribution centre - in a perfect, untouched condition. We have various procedures in place for checking, packing and wrapping these items to ensure there is minimal risk of damage occurring during transit, however, damage can still occur. We endeavour to be as transparent as possible with our customers to ensure they are aware there is always a risk of damage occurring during transit and, if damage does occur, the liability falls onto the buyer.

Some shipping/courier companies offer an insurance for shipments. Please contact us within 24 hrs of a purchase if you’d like to pay for an additional insurance.

To return the item you purchased, please mail it to:

Refunds do not include any shipping and handling charges shown on the packaging slip or invoice. Shipping charges for all returns must be prepaid and insured by you. You are responsible for any loss or damage to hardware during shipment. We do not guarantee that we will receive your returned item. Shipping and handling charges are not refundable. Any amounts refunded will not include the cost of shipping.

Returns, repairs and service

Until the nature of any fault is determined, the resolution Euro Kustoms can offer may vary. Where necessary, the item may need to be returned to determine fault/issue (see RETURNING ITEMS below regarding freight costs).

Once the fault/issue is clarified, Euro Kustoms may offer replacement parts to the customer. Other alternatives may be offered to the satisfaction of both parties.

Where replacement is not possible, any refund offered may be less than the sale price, depending upon any contribution the owner may have made to the fault/failing.

Where the customer has contributed to the failure, or been misleading in their description of their issues, Euro Kustoms may not accept the warranty claim. If the warranty claim is rejected, the item is to be returned to the customer at the customer cost. Freight cost not to exceed original freight cost. Where item was purchased with free postage, freight costs are to be set at 20% of the item cost. Payment to be made to Euro Kustoms within 14 days of being notified of warranty rejection. Storage fees to apply beyond this time.

Where money is owed to Euro Kustoms for replacement and postage due to incorrect fitting of product, Euro Kustoms is entitled to hold onto the item until payment is made. Storage fees to apply beyond 14 days at 5% of the original product cost until the credit expires.

The warranty is considered void if the item has been modified, altered or tampered with by a person (or persons) not authorised by Euro Kustoms service.

At no time is Euro Kustoms liable to pay any labour cost to fitting or re-fitting of a faulty product.

If a part has been incorrecty purchased or incorrectly sent Euro Kustoms will work with the customer and the costs of the order will be covered by whoever is at fault. If Euro Kustoms is responsibile for sending the incorrect item we will work with the customer to either exchange it for the correct part or organise a refund for the order amount only. At no time is Euro Kustoms liable to pay any additional labour costs incurred

If the part has been altered in anyway to its original state the warranty, return or exchange may be void

**Ensure you read the RETURNING ITEMS information below prior to returning any product.**

Returning Items

If for any of the above reasons you are required to return an item, the following steps need to be followed:

Email info@EuroKustoms.com.au stating your order number, the item/s you wish to return, and the reason for the return.

Our customer service department will review your email and, if applicable, issue you a return authorisation (invoice) number which must be included on the address label. All other relevant information will be sent to you at this time.

Euro Kustoms will not accept the return of any item/s without an RMA attached.

To enable Euro Kustoms to continue offering the very best price, freight arrangements vary depending upon the time that has expired since purchase.

Dispatch

Items are generally dispatched within 1-5 business days after payment is cleared however, please allow approximately 7- 10 business days for it to arrive. Buyers will be able to trace the delivery online with a unique tracking number.

Buyers have the full responsibility to provide us with the correct delivery address and mobile phone number on the checkout page before payment. Courier providers (not Australia Post) normally contact the buyer prior to the delivery day, however this is not always the case.

Any changes to address after checkout will not be considered as valid.

Euro Kustoms is not liable for any delay, losses and/or damage of items due to changes of delivery address after checkout, or mistakes made by buyers. This also includes failure to provide an answered phone number which is essential to facilitate delivery of bulky freight. Please be aware that PO Boxes cannot receive items above 25kg or longer than 1 metre. We highly recommend that you change your delivery address to a workplace for items that are large and bulky.

Where goods are sent through Australia Post, the buyer may receive a card in their letterbox indicating their item is available for pickup from their local post office.

A redelivery fee will be charged to buyers for items that are undeliverable and/or returned to AGR due to incorrect delivery address or unsuccessful delivery. Items will only be delivered during normal business hours (9am to 5pm) on weekdays. Delivery is not available on weekends, public holidays or after business hours.