CSF Audi C8 RS6/RS7 High-Performance Intercooler System

-

Fast Dispatch on In Stock Items

-

100% Original & Quality Guarantee

-

Free Customer Support

Following our debut of our world exclusive All-Aluminum Radiator for the B8 S4/S5, we are excited to announce another world’s first release: CSF’s highly anticipated High-Performance Intercooler System for the new C8 RS6 and RS7.

We’ve teamed up with leading VAG specialists from Southern California, Pacific German, to bring this critical intercooler system to market, unlocking the full potential and increasing power goals of the new C8 platform.

CSF has again teamed up with strategic manufacturing partners, PWR, to bring Formula-1 performance to the aftermarket.

Design & Engineering

| OEM | CSF by PWR | |

|---|---|---|

| # Of Tubes | 22 | 45 |

| Tube Height | 7mm | 3mm Rolled Tube |

| Fin Height | 7mm | 4.85mm |

| Design | Crimped w/ Gasket Cast Endtanks |

100% TIG Welded CNC Billet End Tanks |

Core Technology

The most important feature of the CSF by PWR RS6/RS7 Intercooler System is the Formula-1 grade intercooler core. CSF’s strategic relationship with PWR has allowed the inclusion of this core, which is unlike any other available in the performance aftermarket.

- 3mm tall, rolled tubes with turbulated inner fins maximize the dissipation of heat from the charge air flowing through the pressure side of the intercooler core

- The 4.85mm tall multi-louvered fin is the most efficient fin in the high-performance industry, with performance similar to PWR’s Formula-1 grade race intercooler cores

Proven on CSF’s similar air-to-air twin intercooler systems, for both Porsche 992 Turbo/S and GT2RS, these cores eliminate heat soak and lower Intake Air Temperatures (IATs) to allow maximum performance of the vehicle for an extended period of demanding driving conditions.

As evident from the dyno testing (see graphs below), one of the biggest advantages of CSF’s new C8 RS6/RS7 Intercooler System is the recovery speed in dissipating heat from the turbocharger system.

With the OEM intercoolers, the new C8 platform starts to exhibit heat soak and run-away increases in IATs, which then triggers the ECU system to pull timing out of the engine and subsequently lowers performance.

CNC Machined Billet End Tanks

As with our other products produced through our PWR partnership, our new RS6/RS7 Intercoolers feature 100% TIG-welded machined billet aluminum end tanks vs. the OEM crimped cast aluminum end tanks. This feature is not only aesthetically pleasing, but is also stronger for longevity and durability on high-performance vehicles. The CNC machined billet end tanks are ready to withstand increased boost pressures from bolt-on modifications, higher performance tunes, as well as upgraded turbochargers.

With the enthusiasm that RS6/RS7 customers have for their vehicles, the platform is already pushing past 800 WHP (on its way to 4-digit power levels) and the CSF intercoolers are one of the critical components in reaching these power goals.

Dyno Testing

In-depth engineering processes and testing alongside leading VAG tuning/supercharger specialist, VF Engineering, and Pacific German allowed us to make this high-level vehicle’s components just as refined as the vehicle itself.

-

Installation and Dyno Testing at VF Engineering

-

Installed on Dave’s RS6 (@drakce_official)

We tested the CSF intercooler upgrade with a tuned RS6 at VF Engineering using their in-house Mustang four wheel dyno. In doing so, we were able to see real world abuse on the stock intercoolers by starting with a tuned RS6, performing several back-to-back dyno pulls with 50 seconds cool down in between pulls (1-minute intervals with 10 second pulls). We then flashed the car to the OEM tune and ran the same back-to-back pulls on the dyno. Once we had the data collected for the OEM intercoolers, we removed the bumper cover and swapped out the factory units for the upgraded CSF intercoolers, and immediately tested the car again using the same methodology and controlled testing, with a OEM tune and then flashing onto the vehicle, the VF Engineering Stage-2 performance tune.

The dyno cell was 8°F warmer in the afternoon, during the testing with the CSF intercoolers installed, than the morning tests of the OEM intercoolers. However, we saw a huge improvement despite the warmer conditions. With the OEM intercoolers, the temperature rose 20°F on average every pull on the dyno. With the CSF intercoolers, the temperature dropped 4°F on average every pull on the dyno. Some pulls at peak temperatures were 30°F cooler with the upgraded CSF intercoolers compared to the OEM units. The OEM intercoolers began to show signs of heat soak around the 3rd pull, however with the CSF intercoolers recovery was nearly instant and showed minimal signs of heat soak even after the 5th pull.

Tyler Setterstrom, Lead Technician at Pacific German

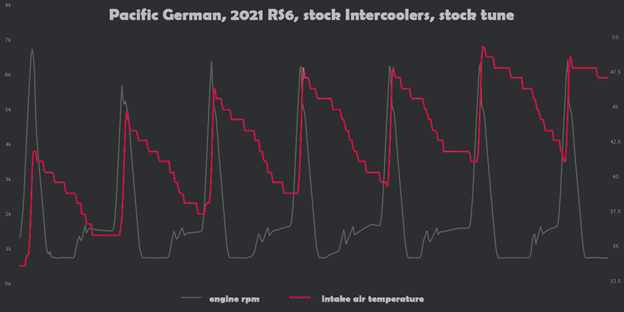

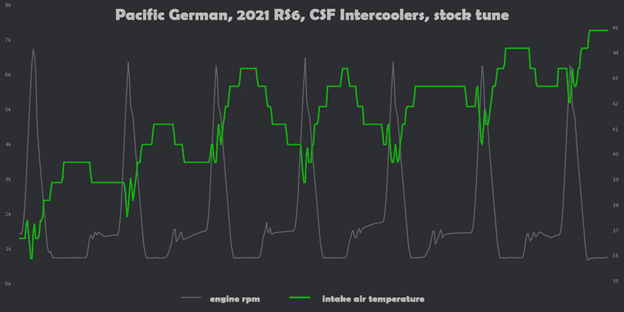

These two graphs show the comparison of OEM (Left) and CSF Intercoolers (Right) with a factory OEM engine tune on an Audi C8 RS6. As you can see from the graphs above, the OEM intercoolers start to exhibit heat soak early on in the testing, already starting to affect performance on the 3rd dyno pull. IATs go up with engine speed. With the CSF intercoolers, the temperature drops as engine speed increases, and recovery between dyno pulls is very quick.

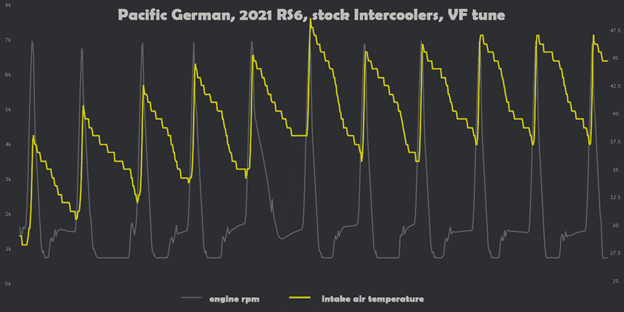

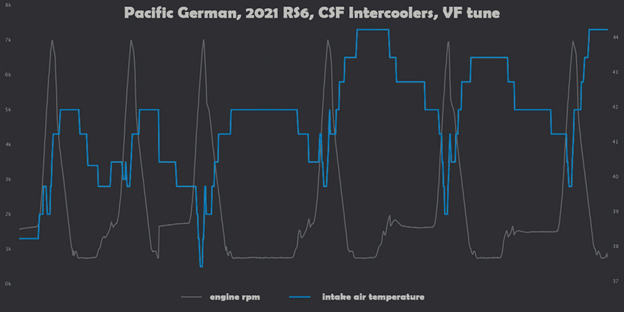

The second set of graphs compares the OEM (Left) and CSF Intercoolers (Right) with VF Engineering Stage-2 engine performance software. In these graphs, like the previous ones as well, the OEM intercoolers allow for heat to rise as engine speed increases. With the CSF Intercoolers, the intake air temperatures drop as engine speed increases. IATs are much more stable with the upgraded CSF units compared to the OEM intercoolers.

Maximum performance, increased recovery speed, stronger design and more power – another industry-leading design, exclusively by CSF.

CSF High-Performance Intercooler System Features (CSF #8194):

-

Eliminates Heat Soak and Lowers Intake Air Temperatures (IATs) for Maximum Performance in High-Performance and Race Conditions

- Stage 1 (Stock Tune) +20 WHP / +18 WTQ*

- Stage 2 (With High-Performance Tune) +10 WHP / +20 WTQ*

- Formula-1 Performance Grade Core by PWR (2-Row Core Featuring Rolled Tubes w/ Inner Fins)

- CNC Machined Billet End Tanks

- 100% TIG Welded vs. OEM Style Gasket and Crimped End Tanks for Maximum Durability

- OEM Style Inlet/Outlet Connections for Precise Fitment With All OEM Components

- True Plug-and-Play “Drop-in Fit” Installation Requires Absolutely No Modifications

- Made in the USA at PWR North America

* Compared to OEM Intercoolers With Same-Day Dyno Testing by VF Engineering

-

Complete Set Fits:

- 2020+ Audi C8 RS6/RS7

- OEM # 4K0 145 805 P (Left) & 4K0 145 806 B (Right)

Due to the complexities and machining time of manufacturing these intercoolers, production runs are limited.

Following our debut of our world exclusive All-Aluminum Radiator for the B8 S4/S5, we are excited to announce another world’s first release: CSF’s highly anticipated High-Performance Intercooler System for the new C8 RS6 and RS7.

We’ve teamed up with leading VAG specialists from Southern California, Pacific German, to bring this critical intercooler system to market, unlocking the full potential and increasing power goals of the new C8 platform.

CSF has again teamed up with strategic manufacturing partners, PWR, to bring Formula-1 performance to the aftermarket.

Design & Engineering

| OEM | CSF by PWR | |

|---|---|---|

| # Of Tubes | 22 | 45 |

| Tube Height | 7mm | 3mm Rolled Tube |

| Fin Height | 7mm | 4.85mm |

| Design | Crimped w/ Gasket Cast Endtanks |

100% TIG Welded CNC Billet End Tanks |

Core Technology

The most important feature of the CSF by PWR RS6/RS7 Intercooler System is the Formula-1 grade intercooler core. CSF’s strategic relationship with PWR has allowed the inclusion of this core, which is unlike any other available in the performance aftermarket.

- 3mm tall, rolled tubes with turbulated inner fins maximize the dissipation of heat from the charge air flowing through the pressure side of the intercooler core

- The 4.85mm tall multi-louvered fin is the most efficient fin in the high-performance industry, with performance similar to PWR’s Formula-1 grade race intercooler cores

Proven on CSF’s similar air-to-air twin intercooler systems, for both Porsche 992 Turbo/S and GT2RS, these cores eliminate heat soak and lower Intake Air Temperatures (IATs) to allow maximum performance of the vehicle for an extended period of demanding driving conditions.

As evident from the dyno testing (see graphs below), one of the biggest advantages of CSF’s new C8 RS6/RS7 Intercooler System is the recovery speed in dissipating heat from the turbocharger system.

With the OEM intercoolers, the new C8 platform starts to exhibit heat soak and run-away increases in IATs, which then triggers the ECU system to pull timing out of the engine and subsequently lowers performance.

CNC Machined Billet End Tanks

As with our other products produced through our PWR partnership, our new RS6/RS7 Intercoolers feature 100% TIG-welded machined billet aluminum end tanks vs. the OEM crimped cast aluminum end tanks. This feature is not only aesthetically pleasing, but is also stronger for longevity and durability on high-performance vehicles. The CNC machined billet end tanks are ready to withstand increased boost pressures from bolt-on modifications, higher performance tunes, as well as upgraded turbochargers.

With the enthusiasm that RS6/RS7 customers have for their vehicles, the platform is already pushing past 800 WHP (on its way to 4-digit power levels) and the CSF intercoolers are one of the critical components in reaching these power goals.

Dyno Testing

In-depth engineering processes and testing alongside leading VAG tuning/supercharger specialist, VF Engineering, and Pacific German allowed us to make this high-level vehicle’s components just as refined as the vehicle itself.

-

Installation and Dyno Testing at VF Engineering

-

Installed on Dave’s RS6 (@drakce_official)

We tested the CSF intercooler upgrade with a tuned RS6 at VF Engineering using their in-house Mustang four wheel dyno. In doing so, we were able to see real world abuse on the stock intercoolers by starting with a tuned RS6, performing several back-to-back dyno pulls with 50 seconds cool down in between pulls (1-minute intervals with 10 second pulls). We then flashed the car to the OEM tune and ran the same back-to-back pulls on the dyno. Once we had the data collected for the OEM intercoolers, we removed the bumper cover and swapped out the factory units for the upgraded CSF intercoolers, and immediately tested the car again using the same methodology and controlled testing, with a OEM tune and then flashing onto the vehicle, the VF Engineering Stage-2 performance tune.

The dyno cell was 8°F warmer in the afternoon, during the testing with the CSF intercoolers installed, than the morning tests of the OEM intercoolers. However, we saw a huge improvement despite the warmer conditions. With the OEM intercoolers, the temperature rose 20°F on average every pull on the dyno. With the CSF intercoolers, the temperature dropped 4°F on average every pull on the dyno. Some pulls at peak temperatures were 30°F cooler with the upgraded CSF intercoolers compared to the OEM units. The OEM intercoolers began to show signs of heat soak around the 3rd pull, however with the CSF intercoolers recovery was nearly instant and showed minimal signs of heat soak even after the 5th pull.

Tyler Setterstrom, Lead Technician at Pacific German

These two graphs show the comparison of OEM (Left) and CSF Intercoolers (Right) with a factory OEM engine tune on an Audi C8 RS6. As you can see from the graphs above, the OEM intercoolers start to exhibit heat soak early on in the testing, already starting to affect performance on the 3rd dyno pull. IATs go up with engine speed. With the CSF intercoolers, the temperature drops as engine speed increases, and recovery between dyno pulls is very quick.

The second set of graphs compares the OEM (Left) and CSF Intercoolers (Right) with VF Engineering Stage-2 engine performance software. In these graphs, like the previous ones as well, the OEM intercoolers allow for heat to rise as engine speed increases. With the CSF Intercoolers, the intake air temperatures drop as engine speed increases. IATs are much more stable with the upgraded CSF units compared to the OEM intercoolers.

Maximum performance, increased recovery speed, stronger design and more power – another industry-leading design, exclusively by CSF.

CSF High-Performance Intercooler System Features (CSF #8194):

-

Eliminates Heat Soak and Lowers Intake Air Temperatures (IATs) for Maximum Performance in High-Performance and Race Conditions

- Stage 1 (Stock Tune) +20 WHP / +18 WTQ*

- Stage 2 (With High-Performance Tune) +10 WHP / +20 WTQ*

- Formula-1 Performance Grade Core by PWR (2-Row Core Featuring Rolled Tubes w/ Inner Fins)

- CNC Machined Billet End Tanks

- 100% TIG Welded vs. OEM Style Gasket and Crimped End Tanks for Maximum Durability

- OEM Style Inlet/Outlet Connections for Precise Fitment With All OEM Components

- True Plug-and-Play “Drop-in Fit” Installation Requires Absolutely No Modifications

- Made in the USA at PWR North America

* Compared to OEM Intercoolers With Same-Day Dyno Testing by VF Engineering

-

Complete Set Fits:

- 2020+ Audi C8 RS6/RS7

- OEM # 4K0 145 805 P (Left) & 4K0 145 806 B (Right)

Due to the complexities and machining time of manufacturing these intercoolers, production runs are limited.

Return Policy

Shipping

We understand how difficult it can be to find good quality parts at affordable prices. Our goal is to offer reliable parts at a price everyone can afford. We send out hundreds of parts every week through various courier companies. Unfortunately these companies do not offer freight insurance on our larger product range.

Please note that with this product range we do offer shipping, however, these items are sent at buyer risk. Therefore, if you have ordered one of these panels and it sustains any damage during transit the onus falls onto the buyer. Obviously we are supplying a brand-new product and we intend for the product to arrive in the same condition it leaves our distribution centre - in a perfect, untouched condition. We have various procedures in place for checking, packing and wrapping these items to ensure there is minimal risk of damage occurring during transit, however, damage can still occur. We endeavour to be as transparent as possible with our customers to ensure they are aware there is always a risk of damage occurring during transit and, if damage does occur, the liability falls onto the buyer.

Some shipping/courier companies offer an insurance for shipments. Please contact us within 24 hrs of a purchase if you’d like to pay for an additional insurance.

To return the item you purchased, please mail it to:

Refunds do not include any shipping and handling charges shown on the packaging slip or invoice. Shipping charges for all returns must be prepaid and insured by you. You are responsible for any loss or damage to hardware during shipment. We do not guarantee that we will receive your returned item. Shipping and handling charges are not refundable. Any amounts refunded will not include the cost of shipping.

Returns, repairs and service

Until the nature of any fault is determined, the resolution Euro Kustoms can offer may vary. Where necessary, the item may need to be returned to determine fault/issue (see RETURNING ITEMS below regarding freight costs).

Once the fault/issue is clarified, Euro Kustoms may offer replacement parts to the customer. Other alternatives may be offered to the satisfaction of both parties.

Where replacement is not possible, any refund offered may be less than the sale price, depending upon any contribution the owner may have made to the fault/failing.

Where the customer has contributed to the failure, or been misleading in their description of their issues, Euro Kustoms may not accept the warranty claim. If the warranty claim is rejected, the item is to be returned to the customer at the customer cost. Freight cost not to exceed original freight cost. Where item was purchased with free postage, freight costs are to be set at 20% of the item cost. Payment to be made to Euro Kustoms within 14 days of being notified of warranty rejection. Storage fees to apply beyond this time.

Where money is owed to Euro Kustoms for replacement and postage due to incorrect fitting of product, Euro Kustoms is entitled to hold onto the item until payment is made. Storage fees to apply beyond 14 days at 5% of the original product cost until the credit expires.

The warranty is considered void if the item has been modified, altered or tampered with by a person (or persons) not authorised by Euro Kustoms service.

At no time is Euro Kustoms liable to pay any labour cost to fitting or re-fitting of a faulty product.

If a part has been incorrecty purchased or incorrectly sent Euro Kustoms will work with the customer and the costs of the order will be covered by whoever is at fault. If Euro Kustoms is responsibile for sending the incorrect item we will work with the customer to either exchange it for the correct part or organise a refund for the order amount only. At no time is Euro Kustoms liable to pay any additional labour costs incurred

If the part has been altered in anyway to its original state the warranty, return or exchange may be void

**Ensure you read the RETURNING ITEMS information below prior to returning any product.**

Returning Items

If for any of the above reasons you are required to return an item, the following steps need to be followed:

Email info@EuroKustoms.com.au stating your order number, the item/s you wish to return, and the reason for the return.

Our customer service department will review your email and, if applicable, issue you a return authorisation (invoice) number which must be included on the address label. All other relevant information will be sent to you at this time.

Euro Kustoms will not accept the return of any item/s without an RMA attached.

To enable Euro Kustoms to continue offering the very best price, freight arrangements vary depending upon the time that has expired since purchase.

Dispatch

Items are generally dispatched within 1-5 business days after payment is cleared however, please allow approximately 7- 10 business days for it to arrive. Buyers will be able to trace the delivery online with a unique tracking number.

Buyers have the full responsibility to provide us with the correct delivery address and mobile phone number on the checkout page before payment. Courier providers (not Australia Post) normally contact the buyer prior to the delivery day, however this is not always the case.

Any changes to address after checkout will not be considered as valid.

Euro Kustoms is not liable for any delay, losses and/or damage of items due to changes of delivery address after checkout, or mistakes made by buyers. This also includes failure to provide an answered phone number which is essential to facilitate delivery of bulky freight. Please be aware that PO Boxes cannot receive items above 25kg or longer than 1 metre. We highly recommend that you change your delivery address to a workplace for items that are large and bulky.

Where goods are sent through Australia Post, the buyer may receive a card in their letterbox indicating their item is available for pickup from their local post office.

A redelivery fee will be charged to buyers for items that are undeliverable and/or returned to AGR due to incorrect delivery address or unsuccessful delivery. Items will only be delivered during normal business hours (9am to 5pm) on weekdays. Delivery is not available on weekends, public holidays or after business hours.